Process Description

The objective of the SPM-500 Flash Tank Process is to separate a mixture of the two paraffins hexane (C6) and heptane (C7) by virtue of the difference in their boiling point temperatures. The separated products are then sent to other units for further processing.

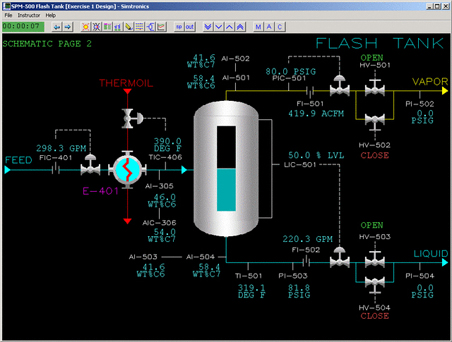

Instrumentation

The mixture feed flow loop is outfitted with a composition analyzer that measures weight percent hexane and heptane (AI-305 and AI-306 respectively). Feed temperature is controlled by TIC-406 and flow is controlled by flow controller FIC-401.

The overhead vapor line is outfitted with a composition analyzer that measures weight percent hexane and heptane (AI-501 and AI-502 respectively). Flash Tank pressure is regulated by pressure controller PIC-501. Vapor rate is measure by FI-501. Vapor flow can be blocked in by block valves HV-501 and HV-502. Downstream pressure is measured by PI-502.

The bottoms liquid line is outfitted with a composition analyzer that measures weight percent hexane and heptane (AI-503 and AI-504 respectively). Flash Tank level is controlled by level controller LIC-501. Liquid rate is measure by FI-502. Tank temperature and tank bottom pressure are measured by TI-501 and PI-503 respectively. Liquid flow can be blocked in by block valves HV-503 and HV-504. Downstream pressure is measured by PI-504.